We are the Bay Area's #1 Epoxy Flooring, Concrete Polishing, Sealed

Concrete Flooring, and Concrete Staining services providers.

Started in 2014, we've delivered on time and within budget 98.7% of the time.

We care about our clients and value their time and budgets. We are your

one-stop shop and on-site experts in the field of concrete floor finishing

and coatings services.

Founder - Anthony Z.

About Us

We provide professional

concrete floor sealing services.

%20Large.jpeg)

FAQ: What is Epoxy Flooring?

Usually a two part (resin/hardener) glue, which has high compression strength, is easily designed with color and texture, and can be combined with other materials (silica, vinyl chip flakes, colored quartz) to seal concrete by increasing impact resistance, slip resistance, and tensile strength.

Epoxy High Build / Thin Build

A great option for almost all job types (Light Industrial, Commercial & Retail, Residential) where you're looking for a finished floor which cleans easily, is tough enough to last for years to come, eco-friendly, and highly customizable.

This system is basically a 3-5 step process: prepare substrate, primer substrate, lay base coat, lay top coat. (Other steps include adding slip resistance to specific areas, installing overlays, installing inlays, etc.).

PROS :

Cost effective option for a highly durable floor.

Fast turnaround time, some products ready for light traffic within 6hrs, most ready for common use within 24hrs.

Customizable colors, effects, and inlays.

Eco-friendly, LEED rated and accredited material.

Easy to maintain

CONS:

Not as durable to impact compared to other systems.

Sheen changes with wear.

Is not ready for exterior use without added products.

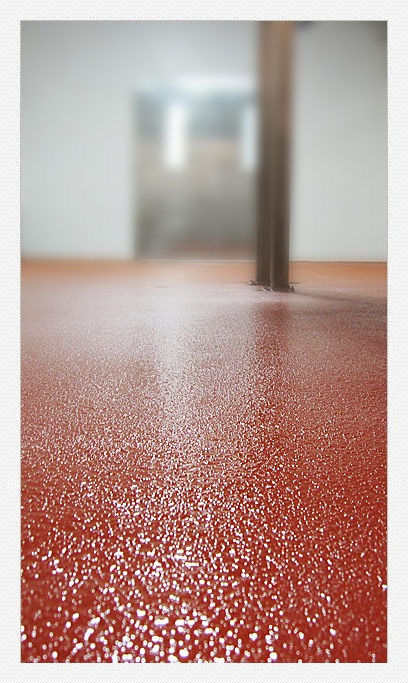

Epoxy Broadcast System:

Silica/Flake/Color Quartz

Fantastic for industrial high traffic areas, residential & commercial garages, commercial kitchens, and anywhere heavy use or impact resistance can be a factor. A combination of Epoxy High Build/Thin Build Systems and a fill element (such as silica sand, color quartz, aluminum oxide, flint silica, vinyl chips, or recycled glass) broadcast into the epoxy to add slip resistance, wear-ability, aesthetic appeal and texture.

These systems are usually between 6-10 steps: prepare substrate, primer substrate, lay base coat, broadcast elements, vacuum and sand, lay topcoat. (Other steps include adding slip resistance to specific areas, additional broadcast coats, installing overlays, installing inlays, etc.)

PROS :

Ready for heavy wear for years to come.

Clean and modern designs with color quarts and flake designs.

Fast turn-around times, usually ready for foot traffic within 24hrs or less from top-coat application.

Eco-friendly, LEED rated and accredited material.

Easy to maintain

CONS:

More costly than less labor-intensive, product heavy, processes.

Sheen changes with wear.

Is not ready for exterior use without added products.

Not as durable to impact compared to other systems.

Slip-resistance wears down cleaning tools faster. (mops, ect...)

Mortar Mix / Urethan Cement Floors

Fantastic for heavy industrial and high traffic areas, residential & commercial garages, commercial kitchens, and anywhere heavy use, impact resistance, and lifetime of floor is a factor. Mortar systems usually combine epoxy and silica sand before application, when installed the finished floor is highly resilient and ready for heavy traffic, wear, and impact. Urethane cement (cementitious urethane mortar) is similar in process and end result, however it uses a high build urethane to seal silica aggregate, added benefits being it's antimicrobial surface, perfect for factory food production (USDA certified) and kitchens.

These systems are usually between 8-12 steps: prepare substrate, primer substrate, lay base-coat, broadcast elements, vacuum and sand, lay topcoat. (Other steps include adding slip resistance to specific areas, installing overlays, installing inlays, etc.)

PROS :

The most durable of all coatings systems available. Highly impact-resistant.

Ready for full temperature extremes, from extreme high-temps to below freezing.

Chemically Resistant to more caustic chemicals.

USDA Approved flooring.

Easy to maintain

CONS:

Most expensive due to product and labor needs from project.

Sheen changes with wear.

Is not ready for exterior use without added products.

Epoxy High Build / Thin Build

A great part of our business comes from helping our clients get the most out of their floors. Updating old spaces giving them new life and making them more functional, or, making a new space unique to your own style and needs.

This system is basically a 3-5 step process: prepare substrate, primer substrate, lay base coat, lay top coat. (Other steps include adding slip resistance to specific areas, installing overlays, installing inlays, etc.).

PROS :

Cost effective option for a highly durable floor.

Fast turnaround time, some products ready for light traffic within 6hrs, most ready for common use within 24hrs.

Customizable colors, effects, and inlays.

Eco-friendly, LEED rated and accredited material.

Easy to maintain

CONS:

Not as durable to impact compared to other systems.

Sheen changes with wear.

Is not ready for exterior use without added products.

Mortar Mix / Urethan Cement Floors

Fantastic for heavy industrial and high traffic areas, residential & commercial garages, commercial kitchens, and anywhere heavy use, impact resistance, and lifetime of floor is a factor. Mortar systems usually combine epoxy and silica sand before application, when installed the finished floor is highly resilient and ready for heavy traffic, wear, and impact. Urethane cement (cementitious urethane mortar) is similar in process and end result, however it uses a high build urethane to seal silica aggregate, added benefits being it's antimicrobial surface, perfect for factory food production (USDA certified) and kitchens.

These systems are usually between 8-12 steps: prepare substrate, primer substrate, lay base-coat, broadcast elements, vacuum and sand, lay topcoat. (Other steps include adding slip resistance to specific areas, installing overlays, installing inlays, etc.)

PROS :

The most durable of all coatings systems available. Highly impact-resistant.

Chemically Resistant to more caustic chemicals.

Ready for full temperature extremes, from extreme high-temps to below freezing.

USDA Approved flooring.

Easy to maintain

CONS:

Most expensive due to product and labor needs from project.

Slip-resistance wears down cleaning tools faster. (mops, ect...)

Is not ready for exterior use without added products.

Sheen changes with wear.

Epoxy Broadcast System:

Silica/Flake/Color Quartz

Fantastic for industrial high traffic areas, residential & commercial garages, commercial kitchens, and anywhere heavy use or impact resistance can be a factor. A combination of Epoxy High Build/Thin Build Systems and a fill element (such as silica sand, color quartz, aluminum oxide, flint silica, vinyl chips, or recycled glass) broadcast into the epoxy to add slip resistance, wear-ability, aesthetic appeal and texture.

These systems are usually between 6-10 steps: prepare substrate, primer substrate, lay base coat, broadcast elements, vacuum and sand, lay topcoat. (Other steps include adding slip resistance to specific areas, additional broadcast coats, installing overlays, installing inlays, etc.)

PROS :

Ready for heavy wear for years to come.

Fast turnaround time, some products ready for light traffic within 6hrs, most ready for common use within 24hrs.

Clean and modern designs with color quarts and flake designs.

Eco-friendly, LEED rated and accredited material.

Easy to maintain

CONS:

More costly than less labor-intensive, product heavy, processes.

Slip-resistance wears down cleaning tools faster. (mops, ect...)

Is not ready for exterior use without added products.

Sheen changes with wear.

Not as durable to impact compared to other systems.

We provide

professional

concrete flooring

services.

About Us

We are the #1 Bay Area Epoxy Flooring, Concrete Polishing, Concrete Sealing, and Concrete Staining services providers. Started in 2014, we've delivered on time and within budget 98.7% of the time. We care about our clients and value their time and budget. We are your one-stop shop and on-site experts in the field of concrete floor finishing.